Factory selling Polyethylene Bottle Molding Machine - Hot Sale Plastic Blow Molding Machine for Multi Layers 220L Plastic Open Top Chemical Drum Making – Tonva

Factory selling Polyethylene Bottle Molding Machine - Hot Sale Plastic Blow Molding Machine for Multi Layers 220L Plastic Open Top Chemical Drum Making – Tonva Detail:

Product Description

Quick Details

![]()

TECHNICAL SPECIFICATION

| Category / 类别 | Item/项目 | Unit /单位 | 20L | 30L |

60L |

120L |

160L |

220L |

500L |

|

| Basic Specification 基本规格 | Raw Material / 材料 |

— |

PE/PP/PA/PVC etc | PE/PP/PA/PVC etc | ||||||

| Dimension /机器外尺寸 |

m |

4.2×2.2×3.0 |

4.8×2.2×3.3 |

5.2×2.4×3.6 |

6.2×2.8×4 | 6.6×3.0×4.2 |

7×3.2×4.5 |

7.5×3.6×5.5 |

||

| Total Weight/机器重量 |

T |

8.5 |

10 |

13 |

18 |

22 |

28 |

32 |

||

| Extrusion System挤出系统 | Screw motor/螺杆电机 |

KW |

18.5 |

|

37 |

55 |

75 |

90 |

110 |

|

| Diameter of screw / 螺杆直径 |

mm |

70 |

80 |

90 |

100 |

100 |

120 |

120 |

||

| Screw L / D ratio /螺杆长径比 |

L/D |

25:1 |

23:1 |

25:1 |

28:1 |

28:1 |

28:1 |

28:1 |

||

| Extruder heating power/螺杆加热功率 |

KW |

18 |

15 |

18 |

20 |

23 |

28 |

30 |

||

| Number of heating zones / 螺杆加热段数 |

pcs |

4 |

4 |

5 |

5 |

6 |

6 |

6 |

||

| Plasticizing capacity / HDPE 挤出量 |

kg/h |

70-80 |

90-100 |

140-160 |

160-200 |

200-250 |

250-300 |

300-350 |

||

| Die Head 模头 | Heating zones /模头加热段数 |

pcs |

4 |

4 |

4 |

5 |

5 |

6 |

6 |

|

| Heating power /模头加热功率 |

KW |

10 |

12 |

13 |

15 |

20 |

28 |

35 |

||

| Number of cavities / 腔数 |

— |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

||

| Clamping System开合模系统 | ||||||||||

| Clamping distance / 合模行程 |

mm |

500 |

550 |

650 |

800 |

900 |

1000 |

1200 |

||

| Open stroke /开合距离 |

mm |

350-850 |

350-900 |

400-1050 |

450-1250 | 700-1600 | 700-1700 |

900-2100 |

||

| Clamping force / 锁模力 |

kn |

200 |

250 |

300 |

122 |

155 |

187 |

221 |

||

| Power consumption能耗 | Total power/机器总功率 |

KW |

61.5 |

84 |

95.5 |

44^16/59-63 |

72-78 |

80-110 |

136-140 |

|

| Air pressure /吹气压力 |

MPa |

0.8 |

0.8 |

0.8 |

0.8 |

0.8 |

0.8 |

0.8 |

||

| Air consumption / 耗气量 |

m3/ min |

0.6/0.4 |

0.8/0.4 |

0.8/0.6 |

1 /0.8 |

0.8 |

1 |

1.1 |

||

| Water consumption / 用水量 |

m3/ h |

0.6/1 | 1/1.2 |

1/1.2 |

1.2/1.5 |

1.5 |

2 |

2.2 |

||

TECHNICAL SPECIFICATION

1.“A”series is applicable for capacity between 10L and 30L.It is widely used in plastic barrel,tool boxes,hollow desk board,chairs ,auto parts and other large and medium -sized plastic hollow products.

2.Adopt accumulator die head ,with high quality nitrogen treatment and hardness of surface,resulting smooth flow and quick parison ejection.

3.ACCumulation head:”FIRST IN FIRST OUT’,FROM 2.8LTO193L

4.Above data is for reference only. Tonva retain the right to modify mechanical structure. Equipment purchase is subject to contact.

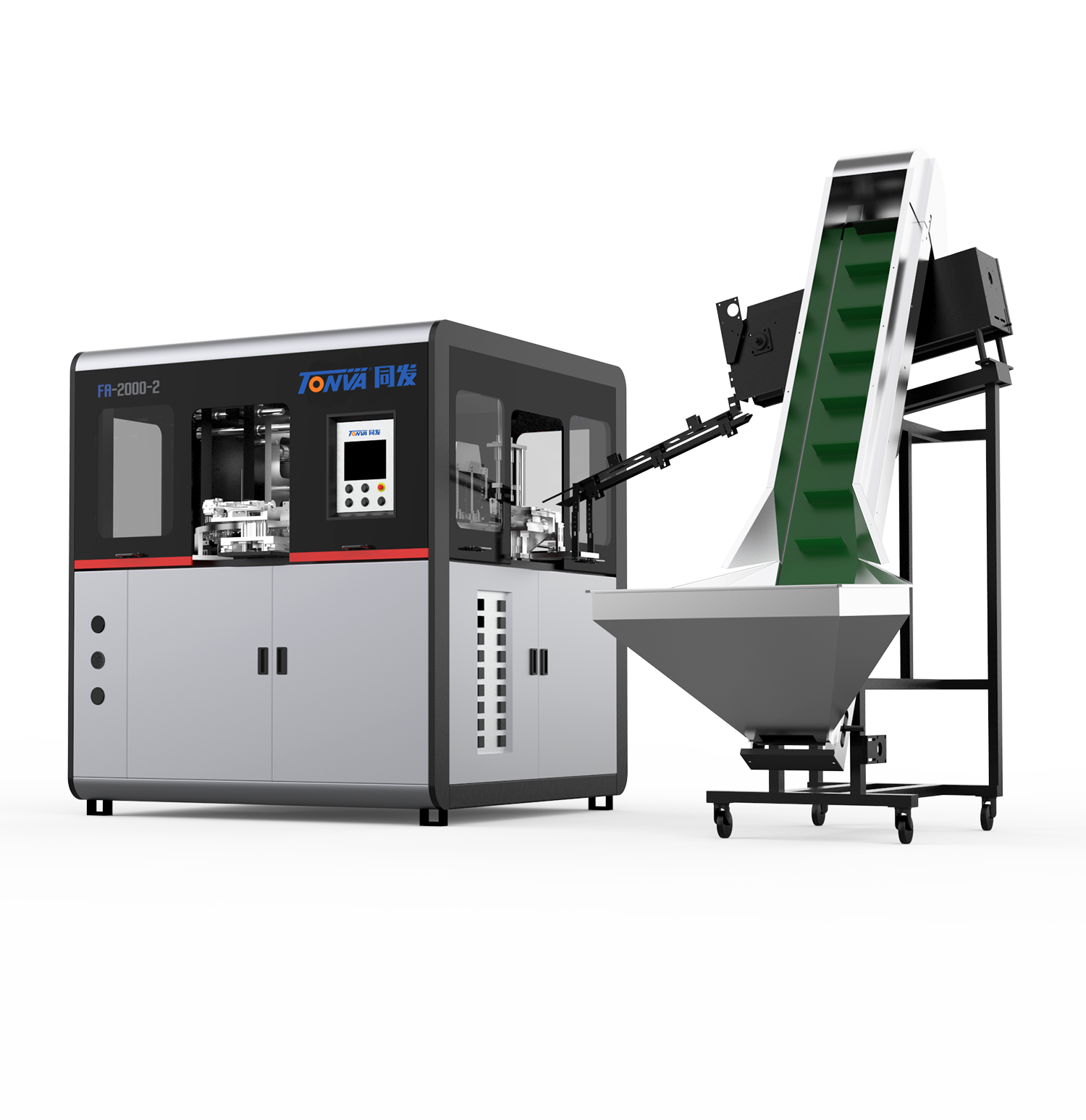

Product detail pictures:

Related Product Guide:

We thinks what clients think, the urgency of urgency to act from the interests of a client position of theory, allowing for greater quality, lessen processing costs, price ranges are much more reasonable, won the new and outdated shoppers the support and affirmation for Factory selling Polyethylene Bottle Molding Machine - Hot Sale Plastic Blow Molding Machine for Multi Layers 220L Plastic Open Top Chemical Drum Making – Tonva , The product will supply to all over the world, such as: Bangkok, Uruguay, Birmingham, We hope we can establish long-term cooperation with all of the customers, and hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need!Welcome all customers both at home and abroad to visit our factory. We hope to have win-win business relationships with you, and create a better tomorrow.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.