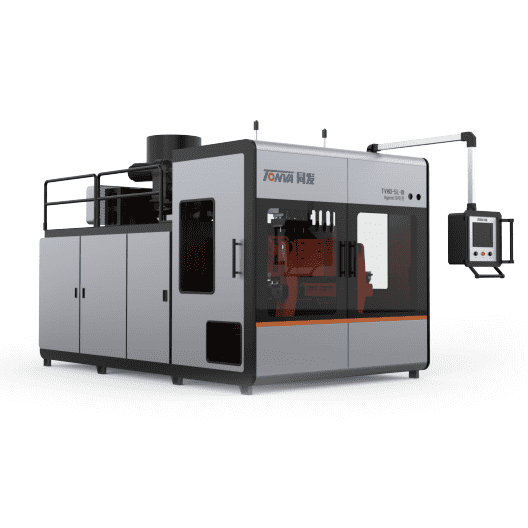

Factory source Bottle Blowing Machine Supplier - MILK BOTTLE MACHINE – Tonva

Factory source Bottle Blowing Machine Supplier - MILK BOTTLE MACHINE – Tonva Detail:

TECHNICAL SPECIFICATION

| Category | Item |

Unit |

100ML-6 |

500ML-6 |

500ML-8 |

1.5L-3 | 1.5L-4 |

| Basic Specification | Raw Material |

— |

PE/PP |

||||

| Dimension |

m |

4.0×2.2×2.2 |

5.3×3.5×2.4 |

5.3×4.5×2.4 |

5.3×2.8×2.4 |

6.0×3.8×2.4 |

|

| Total Weight |

T |

8 |

12 |

12 |

12 |

15 |

|

| Product Capacity |

ml |

100 |

500 |

500 |

1500 |

1500 | |

| Extrusion System | Diameter of screw |

mm |

80 |

90 |

90 |

90 |

100 |

| Screw L/ D ratio |

L/D |

23:1 |

25:1 |

28:1 |

28:1 |

25:1 |

|

| Number of heating zones |

pcs |

4 |

5 |

5 |

5 |

6 |

|

| Extruder drive power |

KW |

22 |

30 |

37 |

37 |

37 | |

| Plasticizing capacity |

kg/h |

75 |

120 |

130 |

130 |

140 |

|

| Die Head | Heating zones |

pcs |

7 |

7 |

9 |

4 |

5 |

| Number of cavities |

—— |

6 |

6 |

8 |

3 |

4 |

|

| Center distance |

mm |

60 |

100 |

100 |

160 |

160 |

|

| Clamping System | Clamping distance |

mm |

150 |

200 |

200 |

200 |

200 |

| Sliding distance |

mm |

450 |

700 |

900 |

550 |

750 |

|

| Open stroke |

mm |

150-300 |

160-360 |

160-360 |

160-360 |

160-360 |

|

| Clamping force |

kn |

100 |

125 |

125 |

125 |

125 |

|

| Power consumption | Air pressure |

Mpa |

0.6-0.8 |

0.6-0.8 |

0.6-0.8 |

0.6-0.8 |

0.6-0.8 |

| Air consumption |

m3 / min |

0.8 |

0.9 |

1 |

1 |

1.1 | |

| Cooling water consumption |

m3/h |

1.5 |

1.5 |

1.5 |

1.5 |

1.8 |

|

| Oil Pump power |

KW |

11 |

15 |

15 |

15 |

18.5 |

|

| Total power |

KW |

59-63 |

72-78 |

75-78 |

72-78 |

94-98 |

|

TECHNICAL SPECIFICATION

1.This model is featured as follows: multi die head, double station and high production. Bottle wall thickness of each cavity is made even with the design of center feeding die head, processed by CNC machine center.

2.Machine uses imported brand for hydraulic components and adopts double proportional valve to control the flow speed and pressure of oil circuit which can also be managed online. Movement of the above is stable and smooth.

3.MOOG 100 Points Parison Controller System can be adopted to further improve product quality.

4.This model can be upgraded into “Hybrid Type” , the carriage moving part of which is designed with servo motor to achieve no noise, easy operation, precise position and swift center-focus on mould.

5.Machine can be designed to work with robot arm, conveyor, leak tester, in-mould label, packaging machine, etc. as per your requirement.

Product detail pictures:

Related Product Guide:

We often persist with the theory "Quality To start with, Prestige Supreme". We are fully committed to delivering our clientele with competitively priced good quality items, prompt delivery and experienced support for Factory source Bottle Blowing Machine Supplier - MILK BOTTLE MACHINE – Tonva , The product will supply to all over the world, such as: kazakhstan, Cologne, Ukraine, We have now a large share in global market. Our company has strong economic strength and offers excellent sale service. Now we have established faith, friendly, harmonious business relationship with customers in different countries. , such as Indonesia, Myanmar, Indi and other Southeast Asian countries and European, African and Latin American countries.

This is a very professional wholesaler, we always come to their company for procurement, good quality and cheap.