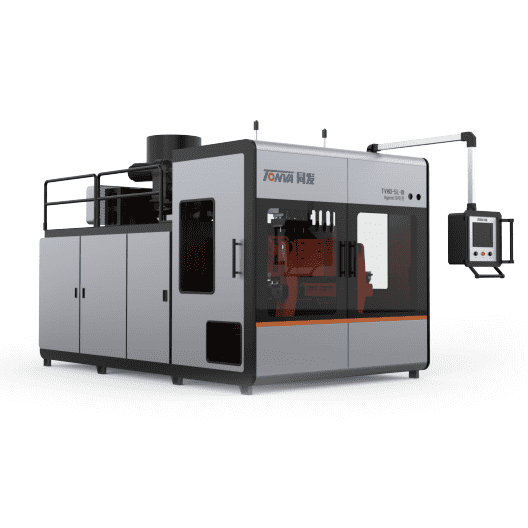

Manufacturing Companies for Bottle Extrusion Blow Moulding Machine - PASTEUR PIPETTER DROPPER / ENEMA MACHINE – Tonva

Manufacturing Companies for Bottle Extrusion Blow Moulding Machine - PASTEUR PIPETTER DROPPER / ENEMA MACHINE – Tonva Detail:

TECHNICAL SPECIFICATION

| Category | Item |

Unit |

1L |

| Basic Specification | Raw Material |

—— |

PE/PP |

| Dimension |

m |

2.8×1.6×2.0 |

|

| Total Weight |

T |

4-5 |

|

| Diameter of screw |

mm |

55 |

|

| Screw L/ D ratio |

L/D |

23:1 |

|

| Extrusion System | Number of heating zones |

pcs |

3 |

| Extruder drive power |

KW |

7.5 |

|

| Plasticizing capacity |

kg/h |

55 |

|

| Heating zones |

pcs |

9 |

|

| Die Head | Number of cavities |

— |

4 |

| Center distance |

mm |

60 |

|

| Clamping System | Sliding distance |

mm |

300/320 |

| Clamping force |

kn |

50 |

|

| Air pressure |

Mpa |

0.6 |

|

| Power consumption | Air consumption |

m3/ min |

0.4 |

| Cooling water consumption |

m3/h |

1 |

|

| Oil Pump power |

KW |

5.5 |

|

| Total power |

KW |

12-20 |

TECHNICAL SPECIFICATION

1. This model is characterized by no pollution, high speed, stability, energy saving and precise position of carriage moving.

2. Machine is manufactured with no hydraulic system but servo motor-control system is adopted to swiftly accurate mould moving position with quick response of strong clamping force. Thus, no-pollution production environment greatly meets requirements of pharmaceutical packaging.

3. High-speed and stable production can amount to over ten thousand pcs per day. And 40% energy can be saved compared to hydraulic system.

4. Newly-designed interior structure of the die head well guarantees the melting plastic comes down straight with no deviation.

Weight error can be controlled to 0.1 gram.

5. Rate of failed products can be effectively lowered as it is simple and easy to learn about machine adjustment and operation.

Product detail pictures:

Related Product Guide:

"Quality first, Honesty as base, Sincere service and mutual profit" is our idea, in order to develop continuously and pursue the excellence for Manufacturing Companies for Bottle Extrusion Blow Moulding Machine - PASTEUR PIPETTER DROPPER / ENEMA MACHINE – Tonva , The product will supply to all over the world, such as: Greek, Slovakia, Malaysia, Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements. We are looking forward to cooperating with friends from all over the world.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.