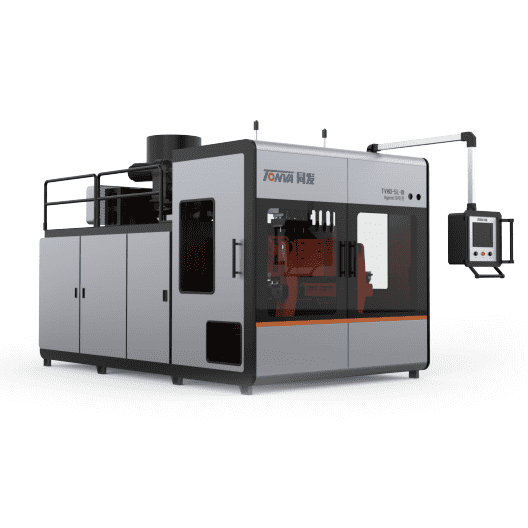

Professional Design Plastic Fuel Tank Blow Molding Machine - BLOW MOLDING MACHINE TVA 20L-500L – Tonva

Professional Design Plastic Fuel Tank Blow Molding Machine - BLOW MOLDING MACHINE TVA 20L-500L – Tonva Detail:

Main parameters of single layer ( 20L — 500L )

|

model |

TVA-20L |

TVA-60L |

TVA-120L |

TVA-20L |

TVA-160L |

TVA-220L |

TVA-500L |

|

Capacity |

20L |

30L |

60L |

120L |

160L |

220L |

500L |

| Clamping distance (mm) |

550 |

550 |

650 |

800 |

900 |

1000 |

1200 |

|

Open stroke (mm) |

300-850 |

350-900 |

400-1050 |

450-1250 |

700-1600 |

700-1700 |

900-2100 |

| Clamping platen size(W*H) |

800X800 |

900X950 |

900X1050 |

1000X1200 |

1100X1300 |

1200X1400 |

1400*1650 |

| Clamping force (KN) |

250 |

250 |

300 |

500 |

800 |

900 |

1000 |

| Extrus i on motor (kw) |

18.5 |

30 |

37 |

55 |

75 |

90 |

110 |

| Extruder heating power (kw) |

10 |

12 |

13 |

15 |

20 |

28 |

35 |

|

Diameter of screw |

70 |

80 |

90 |

100 |

110 |

120 |

130 |

|

L/ D ratio |

23:1 |

23:1 |

25:1 |

28:1 |

28:1 |

28:1 |

28: 1 |

| Plasticizing capacity (kg/h) | 70-80 |

90-100 |

140-160 |

160-200 |

200-250 |

250-300 |

300-350 |

| Storage volume (L) |

3.8 |

5. 5 |

7.4 |

12 |

18 |

22 |

30 |

| Extruder heating power (kw) |

18 |

20 |

23 |

26 |

30 |

35 |

50 |

| Oil pump motor power (kw) |

15 |

22 |

18. 5+4 |

22+4 |

30+4 |

30+4 |

37+4 |

|

Total power (kw) |

61.5 |

84 |

95.5 |

122 |

155 |

187 |

221 |

|

Dimension (L*W*H) M |

4. 2*2. 2*3. 0 |

4. 5*2. 2*3. 3 |

5. 2*2. 4*3. 6 |

6. 2*2. 8*4 |

6. 6*3. 0*4. 2 |

7*3. 2*4. 5 |

8. 0*3. 3*5. 5 |

|

Total Weight (T) |

8.5 |

10 |

13 |

18 |

22 |

28 |

32 |

Main parameters of double layer(20L — 500L)

|

Model |

TVA-20-II |

TVA-30-II |

TVA-60-II |

TVA-120-II |

TVA-160-II |

TVA-220-II |

TVA-500-II |

|

Capacity |

20L |

30L |

60L |

120L |

160L |

220L |

500L |

| Clamping distance (mm) |

550 |

550 |

650 |

800 |

900 |

1000 |

1200 |

|

Open stroke (mm) |

300-850 |

350-900 |

400-1050 |

450-1250 |

700-1600 |

700-1700 |

900-2100 |

| Clamping platen size(W*H) |

800X800 |

900X950 |

900X1050 |

1000X1200 |

1100X1300 |

1200X1400 |

1400*1650 |

| Clamping force (KN) |

250 |

250 |

300 |

500 |

800 |

900 |

1000 |

| Extrusion motor (kw) |

15+15 |

18. 5+18. 5 |

22+15 |

22+22 |

37+22 |

37+37 |

55+37 |

| Heating power (kw) |

13 |

14 |

17 |

19 |

25 |

33 |

42 |

|

Diameter of screw |

65+65 |

70+70 |

80+65 |

80+80 |

90+80 |

90+90 |

100+90 |

|

L/ D ratio |

25:1/25, 1 |

23:1/23:1 |

23:1/25:1 |

23:1/23:1 |

25:1+23:1 |

25: 1/25:1 |

28: 1+25:1 |

| Plasticizing capacity (kg/h) | 70-80 |

90-100 |

140-160 |

160-200 |

200-250 |

250-300 |

300-350 |

| Storage volume (L) |

3.8 |

5. 5 |

7.4 |

12 |

18 |

22 |

30 |

| Extruder heating power (kw) |

18 |

20 |

23 |

26 |

30 |

35 |

50 |

| Oil pump motor power (kw) |

15 |

22 |

18. 5+4 |

22+4 |

30+4 |

30+4 |

37+4 |

|

Total power (kw) |

61.5 |

84 |

95.5 |

122 |

155 |

187 |

221 |

|

Dimension (L*W*H) M |

4. 2*2. 2*3. 3 |

4. 5*2. 2*3. 5 |

5. 2*2. 4*3. 8 |

6. 2*2. 8*4. 2 |

6. 6*3. 0*4. 4 |

7*3. 2*4. 8 |

8. 0*3. 3*5. 7 |

|

Total Weight (T) |

9.2 |

11 |

14 |

19 |

24 |

31 |

35 |

TECHNICAL SPECIFICATION

1.“A” Series is well applied to produce various kinds of blow molded products, such as chemical drum, toolbox kids play toy, chair, auto parts and pallet.Machine can effortlessly stores material in a short time with the design of accumulator die head, and with imported hydraulic control system, it runs more reliably and steadily. We also adopt advanced parison controller system to precisely even the wall thickness of products.

2.Number of layers: 1 layer to 3 layers.

3.Clamping Structure: Three-plate and inclined arm double pull-rod work together with the clamping structure.Plates are big enough to hold large-sized mould and mould opening & closing operates stably. More importantly deformation is no way to appear.

Product detail pictures:

Related Product Guide:

Innovation, excellent and reliability are the core values of our business. These principles today extra than ever form the basis of our success as an internationally active mid-size company for Professional Design Plastic Fuel Tank Blow Molding Machine - BLOW MOLDING MACHINE TVA 20L-500L – Tonva , The product will supply to all over the world, such as: America, San Francisco, Romania, Our aim is to help customers to make more profits and realize their goals. Through a lot of hard work, we establish a long-term business relationship with so many customers all around the world, and achieve win-win success. We will continue to do our best effort to service and satisfy you! Sincerely welcome you to join us!

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.