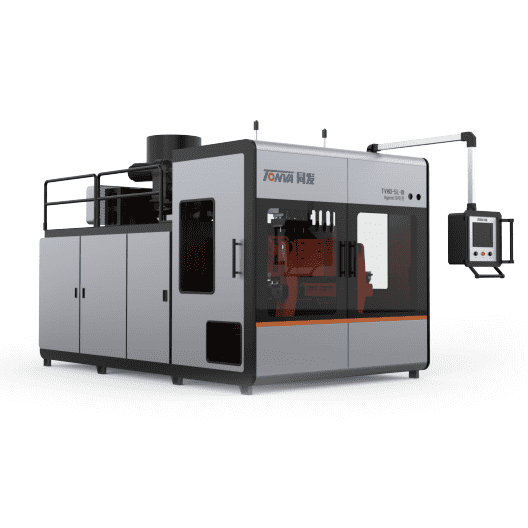

Trending Products Car Fuel Tank Blow Molding Machine - Fuel Bottle Extrusion Blow Molding Machine – Tonva

Trending Products Car Fuel Tank Blow Molding Machine - Fuel Bottle Extrusion Blow Molding Machine – Tonva Detail:

Product Description

hydraulic automatic hollow blowing molding machine, single or multi-station multi-mold head design, using Japan Omron PLC, touch screen control, simple and convenient operation, suitable for machine oil can, washing buckets and other hollow products below 5 l, stable performance, can fully meet the requirements of customers for plastic blowing products.

hydraulic automatic hollow blowing molding machine, single or multi-station multi-mold head design, using Japan Omron PLC, touch screen control, simple and convenient operation, suitable for machine oil can, washing buckets and other hollow products below 5 l, stable performance, can fully meet the requirements of customers for plastic blowing products.

Electronic control system: all process setting, change, retrieval, monitoring, fault diagnosis and other functions are realized on the touch screen, no point contact working principle, durable components.

Hydraulic system: proportional pressure control, equipped with imported famous hydraulic components, stable and reliable.

Plasticizing system: high efficiency plasticizing screw ensures full and uniform plasticizing.

Speed regulation system: frequency conversion speed regulation + alloy steel hard tooth surface reducer, smooth speed regulation, low noise, durable.

Mold opening and closing, mold moving system: beam arm, three-point, central locking mold opening and closing mechanism, to ensure long-term use. The clamping force is balanced, no deformation, and adopts translation mode mechanism (ball linear guide rail), high precision, small resistance and fast speed. Needle blowing rack: integral square needle blowing rack, stable and non-shifting, to ensure smooth product incision.

Technical Specification

1.The number of die head and the clamping stroke listed in the above are set for standard models. Capacity of products in different sizes made on one machine must be no more than the plus or minus 20% of the recommended one.

2.One machine, used for producing products with sizes in variety and capacity in big difference, can be designed with die heads in odd number. This design makes it possible to serve one machine in a multi-way by shutting down one or more die head. Take machine “TVHD-1L-3″ as an example, three die heads for 180ml bottle and two die heads for 500ml bottle.

3.The above models can all be upgraded into aHybrid Type” , the carriage moving part of which is designed with servo motor to achieve no noise, easy operation, precise position and swift center-focus on mould.

4.Above data is for reference only. Tonva retain the right to modify mechanical structure. Equipment purchase is subject to contact.

We normally continually supply you with essentially the most conscientious shopper support, along with the widest variety of designs and styles with finest materials. These attempts include the availability of customized designs with speed and dispatch for Massive Selection for HDPE Plastic Bottles Extrusion Blow Molding Machine Made in China, On account of superior quality and competitive selling price , we’re going to be the current market leader, be sure to don’t wait to contact us by mobile phone or email, in case you are fascinated in any of our products.

Massive Selection for China Plastic Blowing Machine, Blow Molding Machinery, Since the establishment of our company, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it.

Factory Workshop

Our Service

Reply the request and take action in24 hours.

Blowing mould and injection mould made at TONVA original company.

100% Quality inspection before the shipment.

Auxiliary machine for complete line.

Provide training service in TONVA company or clinet’s factory.

Customized design is available as requirements.

Engineer for overseas installation is available

Provide consultation service in request.

Sample Room

Custormers

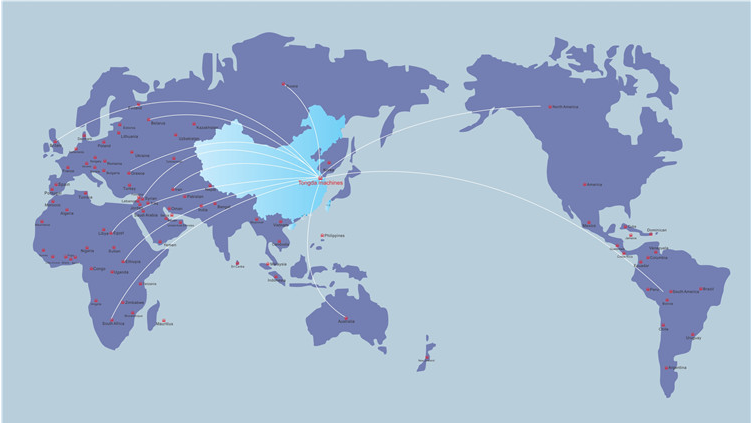

Service Marketing Network

Our machine has been serving customers all over the world.

Packaging & Logistics

Product detail pictures:

Related Product Guide:

We have been ready to share our knowledge of advertising worldwide and recommend you suitable products at most aggressive costs. So Profi Tools present you ideal price of money and we've been ready to create with each other with Trending Products Car Fuel Tank Blow Molding Machine - Fuel Bottle Extrusion Blow Molding Machine – Tonva , The product will supply to all over the world, such as: Bangkok, Zurich, Turkey, Strict quality control is executed in each link of the whole production process.We sincerely hope to establish the friendly and mutual-beneficial cooperation with you. Based on high quality products and perfect pre-sales /after-sales service is our idea, some clients had cooperated with us for more than 5 years.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!