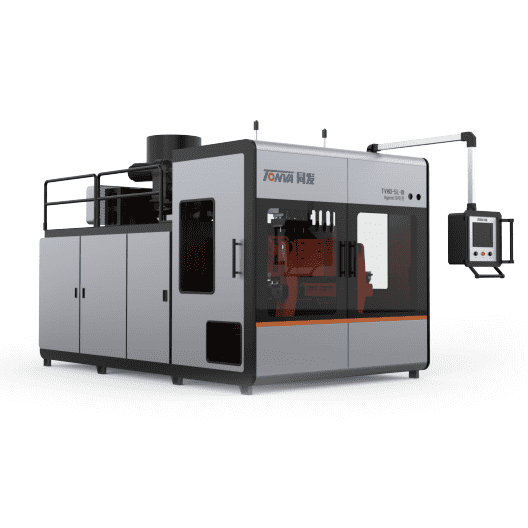

OEM Supply Plastic Jerry Can Blow Molding Machine - FUEL BOTTLE CHEMICAL DRUM CIVIL BARREL MACHINE – Tonva

OEM Supply Plastic Jerry Can Blow Molding Machine - FUEL BOTTLE CHEMICAL DRUM CIVIL BARREL MACHINE – Tonva Detail:

TECHNICAL SPECIFICATION

| Category |

Item | Unit |

1L-4 |

2L-3 |

5L-2 |

12L-2 |

| Basic Specification | Raw Material | — |

PE/PP |

|||

| Dimension | m | 5.3×3.5×2.4 | 5.3×3.5×2.4 |

5.3×4.5×2.4 |

6.0×3.8×2.4 | |

| Total Weight | T |

8 |

12 |

12 |

12 |

|

| Product Capacity | ml |

1000 |

2000 |

5000 |

12000 |

|

| Extrusion System

|

Diameter of screw | mm |

90/80 |

90/80 |

90/80 |

100/90 |

| Screw L / D ratio | L/D |

25:1/23:1 |

25:1/23:1 |

25:1/23:1 |

28:1/25:1 | |

| Number of heating zones | pcs |

5 |

5 |

5 |

7 | |

| Extruder drive power | KW |

30/22 |

30/22 |

30/22 |

45/30 |

|

| Plasticizing capacity |

kg/h |

120 |

120 |

120 |

160 |

|

| Die Head | Heating zones | pcs |

5 |

7 |

5 |

5 |

| Number of cavities | 一 |

4 |

3 |

2 | 2 | |

| Center distance | mm |

150 |

190 |

240 |

280 |

|

| Clamping System | Clamping distance | mm |

200 |

200 |

250 |

350 |

| Sliding distance | mm |

700 |

700 |

650 |

800 |

|

| Open stroke | mm |

240-440 |

240-440 |

230-480 |

330-680 |

|

| Clamping force | kn |

125 |

125 |

125 |

180 |

|

| Air pressure | Mpa |

0.6-0.8 |

0.6-0.8 |

0.6-0.8 |

0.6-0.8 |

|

| Power consumption | Air consumption |

m3/ min |

0.9 |

0.9 |

0.9 | 1 |

| Cooling water consumption |

m3 / h |

1.5 |

1.5 |

1.5 |

1.8 |

|

| Oil Pump power | KW |

11 |

15 |

15 |

18.5 |

|

| Total power | KW |

72-78 |

72-78 |

72-78 |

88-113 |

|

TECHNICAL SPECIFICATION

1.lt is suitable for producing 1L-12L fuel bottle, lubricating oil bottle, etc.

2.Smooth treatment inside the die head with no dead angle in the curve flow runner gives good effect to smoothness and no lines outside and inside the finished products.

3. The effect of multi-layer co-extrusion, with the option of visible line design in the finished product, ensures uniform thickness in layers and the 入-shaped flow runner design inside die head, with less than two hours of color change, create translucent and straight visible line with even width top and bottom.

4. Machine can be equipped with auto deflashing, take-out units for finished product, conveyors for waste material and finished product, in-mould label and leak tester.

5. This model can be upgraded into Hybrid Type” , the carriage moving part of which is designed with servo motor to achieve no noise, easy operation, precise position and swift center-focus on mould.

Factory Workshop

Our Service

Reply the request and take action in24 hours.

Blowing mould and injection mould made at TONVA original company.

100% Quality inspection before the shipment.

Auxiliary machine for complete line.

Provide training service in TONVA company or clinet’s factory.

Customized design is available as requirements.

Engineer for overseas installation is available

Provide consultation service in request.

Sample Room

Custormers

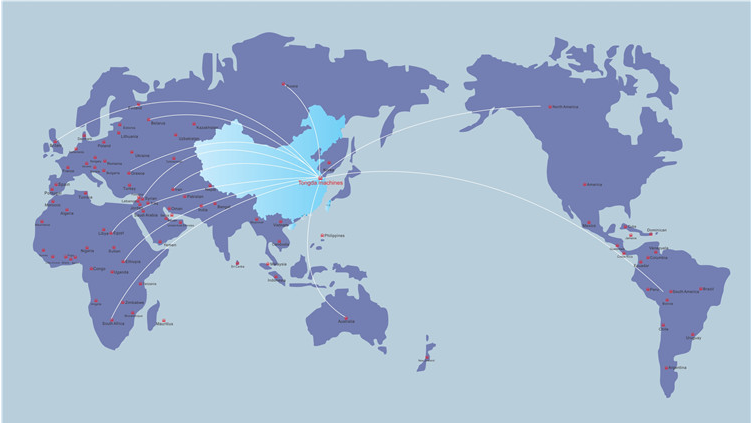

Service Marketing Network

Our machine has been serving customers all over the world.

Packaging & Logistics

Product detail pictures:

Related Product Guide:

We are also specializing in improving the things management and QC method in order that we could retain terrific edge inside the fiercely-competitive small business for OEM Supply Plastic Jerry Can Blow Molding Machine - FUEL BOTTLE CHEMICAL DRUM CIVIL BARREL MACHINE – Tonva , The product will supply to all over the world, such as: New Delhi, Salt Lake City, Danish, Abiding by our motto of "Hold well the quality and services, Customers Satisfaction", So we provide our clients with high quality products and excellent service. Please feel free to contact us for further information.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.