plastic jerry can blow molding making machine fully automatic production scheme

Machine

Mould

Company profile

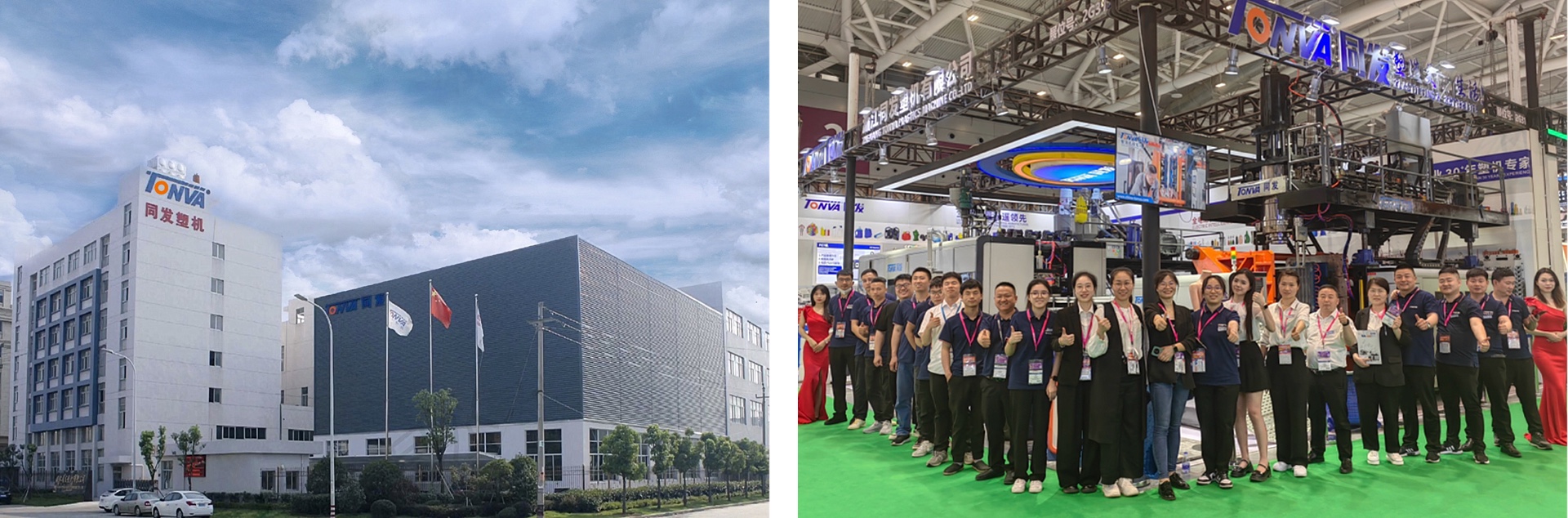

Zhejiang TONVA Plastics Machine Co., Ltd was established in 1993 and is a leader of blow molding machine,stretch blow molding machine,plastic blowing mould manufacturer. As a National Hi-tech Enterprise in China,it has an excellent service team who have more than 25 years of experience in the blow molding industry,and more than 40 R&D engineers to make professional designs. it has passed the quality control system ISO9001:2016 and got CE& SGS certifications with more than 50 patents.

In order to suits different needed of customers,Tonva development different structure of machines like pure electric system, hybrid system,hydraulic system,pneumatic system, to make small plastic blowing parts from 1ml to 50L,single layer to six layers, single color to three colors, single cavity to 10 cavities with a variety of raw materials. such as oil barrels, food jars, cosmetics bottles, detergent bottles, sprayer barrels, pesticide bottles, tool set packaging, Christmas balls, beverage bottles,detergent bottles, plastic toys,pipette,medicine bottles etc.

Tonva also has accumulator type machine to make middle and large plastic hollow products from 10L to 5000L, single layer to 6 layers, single station to double stations. Which suits to make Chemical drums, plastic toys, auto parts, plastic furniture, pallets,road barriers,water tanks,floats etc.

Based on the best reputation and first-class service, TONVA machines won the domestic and foreign customers highly praise and trust.So far, the world-wide sales more than 5000 sets in over 120 countries.

Tonva follows the "quality of survival, innovation and development, market-oriented, service for the purpose" business philosophy, we are willing to WIN-WIN together and plastifying a better life with you!

Factory

Sample Room

Custormers

Overseas service

Packaging & Logistics