Products

-

Piston/Screw air compressor

1.Screw air compressor adopt intelligent control system,automatic loading/unloading regulation,reduce the machine running cost,low noise,environmental protection,reduce energy consumption. 2.Piston air compressor adopt the special water cooling system,high performance middle and after cooler,ensure the compressor running full ady 24 hours with safe operation in low temperature. -

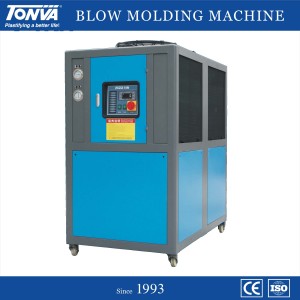

Air Cooled Chiller

1.Air cooled chiller is easy to installion,no need cooling tower. 2.Adopts famous electronic control components processing and manufacturing,Configuration,refrigerant abnormal protection. 3.Corrision resistant fin in air cooling style heat exchanger,manufactured with technics of quadratic flanging fin machine.The machine have the features such as reliable in running,clean easily,strong cooling capicity ,ow noise,long service life and easy to operate. -

Mold Internal labeling Machine

1.Manipulator positioning and labeling accurately,label inlaid firmly,no warping,no wrinkling,no foaming. 2.Labeling and product molding are completed at one time,the product feeling smoothly,novel and beautiful,don't need manual labeling and secondary processing process,and improving production efficiency. 3.Easy to operation,label replace conveniently and wide application range. -

Packing Machine

1.The design of the equipment is simple and practical,and can accurately locate and connect with production lines such as bottle blowing machine ,leak detection machine,visual inspaction machine,labeling machine ,etc. 2.According to the product characteristics and customer spcific requirements,customized for customers with a varity of specifications and shapes of products delicated automatic baler,so as to meet the special requirements of customers in various industries. 3.The automatic plastic bottle packing machine has high adjustability and is suitable for the plasitc bags of different specifications the packing row and column number can be adjusted. -

Bottle Neck Tramming Machine

1.Special designed screw and barrel for PETG raw material makes the raw material melt enough.None dead angle in the dead head flow runner gives beautiful and high transparent surface. 2.Machine can adopt special die head device make bottle inner body with lines. There also have hybrid system,conveyor,leakage tester,robot arm to get fully automatic production line. -

Conveyor

1.The flexible chain conveyor system can prevent material accumulation in the process of conveyoring.It has the characteristics of convenient installation,runing smoothly,low energy consumption,durability and easy maintenance and cleaning. 2.Chain palte conveyor system can bear large load to long distance straight line transport,with high wear resistance and long serive life and other characteristics. -

Fully Automatic Bottle Leakage Detector

TONVA Auxiliary Equipment for complete line,Custtimized design as requirements. 1.Wide application scope,can set the parameters and adjust the angle of testing head according to the product. 2.Adopt differential of high precision pressure sensor to do leak detection,higher leak testing precision. 3.Easy operation with HMI,one-bottle leaking tests automatically,the test demonstrat leak testing information,the defective product reject the production line automatically. -

Fully Automatic PET Blow Molding Machine

Bottle blowing machine: It is a two - step automatic stretching bottle blowing equipment. It is a machine that blows bottles. The most obvious explanation is that it can blow plastic particles (softened into liquid) or done bottle embryos into bottles by certain technological means. -

Shower gel bottles Making Machine

Automatic extrusion blow molding machine can be equipped with conveyor belt, labeling machine, manipulator, leak detection machine, baler and so on according to different needs; Suitable for medicine, toys, cosmetics bottles, beverage bottles, tool sets, oil barrels, etc. -

Dropper Making Machine

The dropper/test tube blow molding machine die head adopts new structure design, the material embryo is more straight and not offset, the product weight error can be less than 0.1g; The operation speed is fast and stable, the daily output can reach more than 100,000, and the energy consumption is 40% less than that of hydraulic equipment. -

Multi-cavity machine(Large output)

The multi-cavity machine runs stably, the output is much higher than the conventional machine, for the output requirements of large customers, welcome to consult -

Jerry Can Making Machine

The model adopts the material storage type die head, the material storage fast running cycle is short, the use of imported hydraulic control system, more stable and durable, the use of the mold control system, to ensure that the wall thickness is more uniform and accurate.