Servo automatic SBM-High speed model

TECHNICAL SPECIFICATION

| Category | Item | Unit | SE-750 |

SE-1500 |

||

| ProductSpecification | Max volume | ml |

750 |

1500 |

||

| Output | pcs/h |

8000-9000 |

9000-10000 | 4000-5000 |

7000-8000 |

|

| Bottle Height | mm |

260 |

360 |

|||

| Body Diameter | mm |

85 |

115 |

|||

| Neck Diameter | mm |

16-38 |

16-38 |

|||

| Mould | Cavity NO. | — |

6 |

8 |

4 |

6 |

| Clamping Storke | mm |

125 |

125 |

|||

| Max Stretch Stroke | mm |

400 |

400 |

|||

| Bottom Mooving Dlroke | mm |

0-50 |

0-50 |

|||

| Power | Total Power | kw |

60 |

65 |

50 |

60 |

| Air | HP Air Compressor | Ain mpa |

2.4/3.0 |

3.6/3.0 |

3.6/3.0 |

4.8/3.0 |

| LPAir Compressor | m3/min mpa |

1.2/1.0 |

1.2/1.0 |

1.2/1.0 |

1.2/1.0 |

|

| Air Dryer +Filter | m3/min mpa |

3.0/3.0 |

4.0/3.0 |

4.0/3.0 |

5.0/3.0 |

|

| Air lank | m3/min mpa |

0.6/3.0 |

1.0/3.0 |

1.0/3.0 |

1.0/3.0 |

|

| Cooling | Water Chiller | P |

3 |

5 |

5 |

8 |

| Machine Specification | Machine(LxWxH) | m |

5.5x1.6x2.0 |

8.5x2.0x2.0 |

3.5x1.6x2.0 |

6.0x2.1x2.0 |

| Machune Weight | kg |

4500 |

7300 |

3500 |

7000 |

|

| Preform Loader | m |

1.1x1.2x2.2 |

2.1x1.2x2.2 |

1.1x1.2x2.2 |

2.0x2.5x2.5 |

|

| Loader Weight | kg |

4800 |

7800 |

3800 |

7500 |

|

TECHNICAL SPECIFICATION

1.The advantages of our machine is energy-saving, highly automated and easy to operate.

2.The whole machine has a high degree of automation,fast and stable action,and high production efficiency.

3.The clamping unit is designed to be servo-driven, energy-saving, stable and efficient, free from noise.

4.Our machine enjorsgreat popularity in other markets.

5. The machine’s operation is easy and simple.

Factory Workshop

Our Service

Sample Room

Custormers

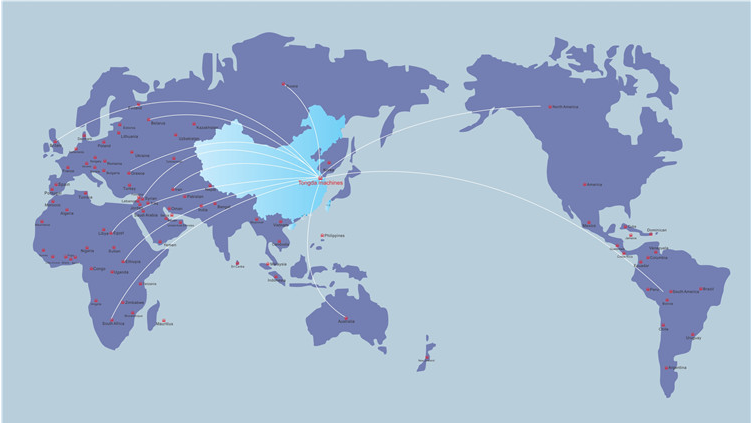

Service Marketing Network

Our machine has been serving customers all over the world.

Packaging & Logistics